As

a building owner, condo board member or property manager, the thought of

modernizing elevators, if you have not done it before, is incredibly confusing

and complicated. Even for property

owners who have gone through the process, it becomes a challenging task because

there are a lot of questions from shareholders[residents, unit owners, owner

groups].

The intent of this quick blog is to help identify when it is time to think about modernizing your elevator equipment.

When should I think about modernizing our elevator equipment? This is a great question and each building will have a different answer. We have buildings that have their elevator equipment for 60 years, we have building’s that would like to replace their elevator equipment every 15-20 years. Our biggest recommended take away from this information is to be informed.

How each elevator is different

Usage – Some buildings are sleepy, some buildings are busy. A care facility and a 9 unit condominium have a very different traffic schedule each day. A busy building will require more maintenance if possible [see maintainability]

Environment – Is the elevator exposed to the elements, is the machine room or hoistway right by the laundry area vent which shoots lint into the machine room, is the elevator room in the garage and cold in the winter and hot in the summer, are there residents in the building that can treat the elevator better and not punch out the buttons or hit the doors on a regular basis.

Reliability expectations – We have a 4 unit buildings that have no elasticity for the elevator being out of service and want their equipment brand new all the time. We have buildings that have 60 year old equipment that are ok with regular shut downs. How does the building feel about their equipment being in service, how reliant is the building on their elevator system.

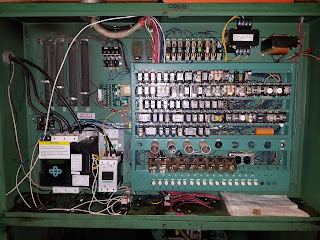

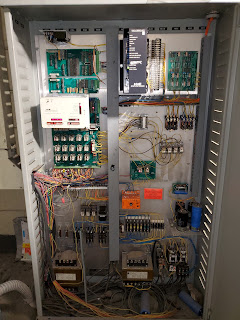

Replacement

equipment availability – Are there parts available to replace the elevator’s

equipment if it requires it? Do you have

a Dover DMC that just had their parts line retired? Do you have a US elevator that is one power outage

away from waiting 4-6 weeks for a new controller because parts are not available.

Equipment replacement philosophy

Proactive replacement – Our recommendation for buildings is to understand the useful life of their elevator systems and how long it will last before it becomes problematic. We[Colley Elevator] try to get in front of buildings to let them know that your elevator has X time period before you may start experiencing problems. These problems can be reliability issues, safety issues, or replacement part acquisition challenges. Talk to your elevator service provider and get some timelines and dates of their recommendations and understand your equipment. We like to see buildings put their elevator in the reserve study and schedule for replacement or at least have funding available. If 5 years go by and the elevator is scheduled to be replaced, if there are no issues with the elevator and a façade repair comes up for replacement, maybe you can push it for a year, but at least you have the funding available and can make a good decision for the building.

Reactive

replacement – What we try and discourage is to run the equipment in the ground

or have a potential doomsday event when your circuit board goes out and there

is not a replacement available and you have to rely on a circuit board repair

shop to give you a moon shot at getting your elevator back running. You can also have an issue at the building

where an elevator installed in 1967 has a leveling problem when someone trips

out of their elevator and there isn’t a clear path to return the elevator back

to a safe and reliable working condition and you have a difficult choice to make

with the elevator contractor to repair[if possible] or replace. If you are in the reactive category you may

also need to deal with how to fund this modernization project quickly which is

its own challenge.

Take away – Learn about your elevator equipment, ask your maintenance technician, have your elevator contractor send you information, come to a board meeting, do an equipment walk through with the key building people. A few important things to take away; elevator modernization is expensive, elevator modernization can be confusing, and elevator modernization may require other trades to be involved. What helps is having someone from the elevator contractor to educate you and give you the tools to be successful in planning.

If

you have any questions or would like additional information feel free to

contact me at CraigZ@colleyelevator.com or

630-766-7230 ext. 107.

Hi Craigz,

ReplyDeleteReached here coz of Googling about Elevators. Being in the industry for so long, We at Cibes make sure to consider each of the points you have mentioned with our customers. There are few out there to add.

Your post has brought things in a simpler manner before the customer. And We liked it.

Regards,

Cibes Lift India

Home Lifts made in Sweden