We have a building who complained about the noise of their

elevator system. It is a 6 stop, 50’ +/-

of travel hydraulic elevator. It is hard

to put a date on the elevator as the building could be from 1970 or 1990, it is

a very non descript building that appears to have been modernized with a newer

controller and a newer submersible hydraulic power unit. About 4 years ago we replaced the elevator

hydraulic cylinder. And haven’t really

had any noise or other structural complaints since. It was interesting when I started to get

complaints about the noise recently, nothing had changed on our end.

What we know

1.

It appears that at one time the oil

line was run underground and it was replaced with an overhead line. Pipes goes from 2” to 2 ½” with a lot of

90’s.

2.

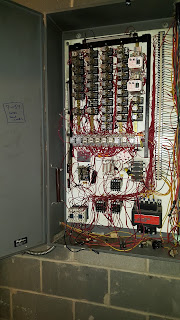

There is a transformer feeding the controller

[assumed initial controller was ordered incorrectly.]

3.

The pit continually gets water in it

4.

It is a higher travel hydraulic

system with a submersible system

5.

Nothing was done to this elevator in

the last 4 years besides typical service call/maintenance issues

Our proposed solution

1.

Install an inflatable muffler inline –

From MEI

2.

Install an isolation coupling inline –

From Maxton Valve

3.

Isolate overhead oil line with more

rubber

4.

Cut out some of the 90’s in the

elevator machine room

[MEI's hydaulic inflatable muffler]

[Maxton valve's isolation coupling]

What we discovered during the installation

1.

Isolation between piston and platen

plate was deteriorated most likely from the constant water and flooding in the

pit which would give the elevator some added vibration.

Before versus after – We had a reduction of noise of 34%

at floors 3, 4 & 5. We did decibel

readings before and after to quantify any changes.

[Before]

[After]

This was an interesting noise issue that I had never seen

come up before at a building. There was

more work that could have completed at the building but it would have required

more time, more work that was outside of the building’s budget at this time.

For more information on the products

MEI - http://www.meielevatorsolutions.com/

Maxton Valve - www.Maxtonvalve.com

As

always feel free to contact us at www.colleyelevator.com, email Craigz@colleyelevator.com or call 630-766-7230.