When

I wrote the 2020 reflection I thought we might be out of the woods with our

pandemic but as I write this we have 510,000 positive covid cases on 12/27/21.

In the last year we had the opportunity to do some great things and work with

some great people. The greatest

experience I have personally have is to work with our great Colley team, I’m

lucky to have such great people around as we enter our 114th year of

being an independent elevator contractor.

Annual

reflection – This year we saw our maintenance portfolio grow

from 1850 to 2020 elevators under contract. This year we ordered/installed 61

Smartrise controller and 4 MCE controllers. 23 cylinders where installed,

37 power units, 74 door packages, 50+ fixture packages, a few machines and a

few complete elevators. We have a team of great people working on every

project to make sure when the product gets here, we have minimum issues from

engineering. Colley expanded our foot print in Bensenville by leasing 12,000 more square feet next door. We gave the 2021 Ellies a great run but did not retain the

title, the title went to our great friends at Midwest Elevator in St. Louis,

MO. Colley started a great new program

called, Colley Cares, which gave out over $12,000 to philanthropic

organizations ranging from substance abuse to food depositories. The Colley team came together to help out

Toys for Tots and a Food Depository this fall/winter with a truck load of gifts

and food to help out those in need. We

work with incredible people who made this all happen and our average employment

is about 10 years. I’m proud to work side by side with everyone here and that

we have a culture of openness at Colley that helps get everyone done at a high

level! Thank you to our coworkers, customers & suppliers for being great!

Elevator

personnel during covid – There is something to be

said for all the elevator mechanics, apprentices and support staff who continues

to go to work during the pandemic. Much appreciation and credit for

elevator personnel team and our great office staff who showed up and did their

job when there was a reason to go and hide.

Post

reflection – Take a look at the great catalog of blog posts in

2021, go back and read some.

1/1/21 - Year in reflection –

Colley Elevator blog – 2020 Elevator blog

1/10/21 - Otis Elevator

Company recalls home elevators – U.S. Consumer Product Safety Commission

1/17/21 – Attention property

managers/building owners – application for certificate of operation

1/24/21 – Hydraulic elevator

modernization – Forest Park, IL

1/31/21 – Elevator sump pump –

water in my elevator pit!

2/6/21 – Elevator picture Hall

of Fame 2020 – Superbowl of Elevators!

2/14/21 – Elevator World –

Preventative maintenance – is technology a complement or substitute

2/21/21 – LULA lift new

construction – 500 N. Michigan – Chicago, IL

2/28/21 – Support for the

Family of Joseph Rosa – Elevator Accident/death NYC

3/7/21 – Elevator pit and

hoistway access is limited to authorized individuals

3/14/21 – Colley Cares –

Colley Elevator gives back

3/21/21 – Elevator World

Chicago Issue – Not just for Code Compliance – Elevator solid state starters

3/28/21 – Hydraulic elevator

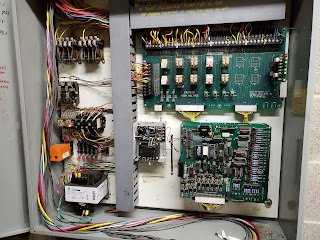

control modernization – Arlington Heights, IL

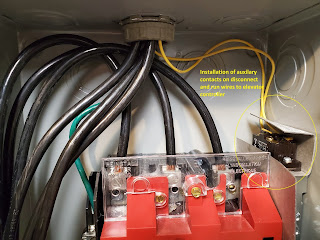

4/4/21 – Elevator disconnect

auxiliary contacts – Elevator controller emergency battery lowering

4/11/21 – American Elevator

Group

4/18/21 – 2020 Top OSHA

violations – Elevator Industry stay frosty

4/25/21 – Guided tour of

Chicago – Elevator project tour

5/2/21 – Colley Cares –

Donation update

5/16/21 – City of Chicago

Fireman’s Emergency operation [FEO] Phase 2 mandate

5/23/21 – IBM Relays – Dover

Elevators US Elevators

5/29/21 – Hydraulic Elevator

Modernization – Oak Park, IL

6/6/21 – Wisconsin Elevator

symposium – QEI training

6/13/21 – Hot and Humid

elevator control rooms – How does it affect my elevator?

6/18/21 – State of Illinois

Fire Marshal moves to ASME A17.1 2019 Elevator code

6/27/21 – Hydraulic elevator

modernization – Chicago, IL

7/5/21 – Colley Elevator

featured in Community Associations Institute Summer Magazine

7/9/21 – Property Manager

Lunch & Learn – Elevator 101

7/17/21 – End of Life/Obsolete

Elevator Equipment – Dover DMC Elevator

7/25/21 – Elevator picture

hall of fame – Volume 1 – 2021

8/9/21 – Elevator Worlds 2021

Ellies – Best Contractor North – Colley Elevator

8/16/21 – Colley Cares – 2nd

Quarter update

8/22/21 – One last chance to

vote – Elevator Worlds 2021 Ellies

9/6/21 – Elevator IOT correlation

– tracker & cylinder gland packing – Labor day

9/12/21 – Hydraulic Elevator

Modernization – Arlington Heights, IL

9/19/21 – State of Illinois 5

year elevator fireman’s recall A17.1 2019 Code modification

9/26/21 – Elevator code

changes – Continuing education – State of Illinois

10/11/21 – NACE 72nd

Annual Convention – New Orleans

10/18/21 – Colley Elevator’s

Holiday Challenge – It just takes a box

10/24/21 – Maxton Valve

continuing education – Colley Elevator

10/31/21 – Traction elevator 4

car modernization – Chicago, IL

11/5/21 – Community

Association Institute of Illinois – CAI – Toys for Tots & food bank

11/14/21 – Colley Cares –

Colley gives back – 3rd Quarter

11/21/21 – Hydraulic elevator

control modernization – Glen Ellyn, IL – US Elevator

12/8/21 – Hydraulic elevator

control modernization – Des Plaines, IL

12/19/21 – Elevator

electrical, fire alarm & other work by othters[WBO] – Elevator

modernization

Blog

reflection – 45 posts in 2021[that is a lot of words,

pictures and time], over 34,000 views, over 169,448 views in the blog’s

history.

Thank

you for everyone who took the time to read the blog. My challenge

for you in 2022 is to make an impact in someone’s life, do something great. Move outside your comfort zone. Turn off the TV, computer or your phone and

spend time with a person or call someone you haven’t talked to in a while. The last two years have been a very lonely time

for many people and together we should be raising each other up. Lets make 2022 a great year and I wish you and your families the best and look forward to working with you in the New Year.

Hey!

Sign up for our mailing list!

If you

have any questions or would like additional information feel free to contact me

at CraigZ@colleyelevator.com or

630-766-7230 ext. 107.

Also

check us out on Instagram @Colleyelevator see what we have been up to.