I was at a building a few years ago for pit ladders and got

a call that they fired their existing company and didn’t have a new one lined

up. When I looked at the pit ladders a

few years ago, I let the building know they should think about replacing their

ESCO equipment that was from 1967. Today

the equipment is 51 years old and still providing the building decent service,

but, they are unhappy with the dependability. When I see equipment this age the question I always ask is "what is the building's expectations of the elevator's reliability". This elevator system has served this building well over the last 51 years. You do not see other building mechanisms that have this much functionality and building interaction last as long as this piece of equipment. Give it a hug, say thank you, it is time to say goodbye.

Controllers

–

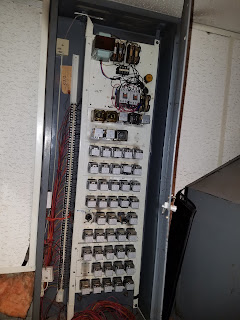

The ESCO controller is a very good controller but as you can see most of the

relays have been replaced with all new relays.

I was told/taught that the replacement relays for these units are

general duty and not the same as the original relays that where designed for

this specific elevator. While less

expensive then replacing the elevator controller in our experience this

experiment only upsets everyone involved; building owner, elevator technician and

elevator company when the desired results are not what everyone thought after dropping a good amount of money for replacing them all 25+ years ago we tried this trick in a complex with 12 elevators and it wasn't good.

Cylinder

–

The elevator was installed in 1967, this most likely means it has a single bulk

head, which means if the controllers are replaced the cylinders need to be

replaced as well.

Door

operator – The GAL MOD is a very dependable door operator, it has

lasted 51 years and is still servicing the building reliably. Any piece of equipment that works as much as

the door operator does get worn out from all the cycles it performs and will be

less dependable then it once was.

Car

& hall buttons – The buttons are having

issues with sticking. Now, you can

change all the buttons with new/old ones or just order new buttons, but you still have what is behind the curtains.

Motor

starters – This is probably the most robust piece of equipment on

the elevator system. The 2 starter Across The Line[ATL] starter set up by

Furnas. They have great big contacts and

can last a very long time with the proper maintenance.

Power

unit – Good robust power unit that has a terrible design with

the motor above the pump and the pump on a 90 degree. Not sure why this was a good idea but it took

a simple design and created a pump/motor replacement challenge[if the need ever

arose]. Probably vertical space saving. The ESCO valve appears to have

been replaced with an EECO valve 15-20 years ago. The longer I am involved in the business the more appreciation I have for dry power units and their longevity and ability to serve building's more efficiently.

Take

away

– I was just talking to coworker about buildings that hit that 40-50 year mark

and they have all these repairs required because buildings during this era

where built to last 40 years. Windows,

tuck pointing, façade, roofs, environmental systems, parking lots, etc all seem

to have issues at the same time. I’m a

proponent of getting reserve studies so as a building you know when you should have

X dollars in the bank for each capital improvement so you don’t get caught with

all these improvements hitting you at the same time. Most residential buildings

I walk into are not flush with money in their reserves so expenses such as

elevator modernization causes a huge impact and funding issue. If you need a good reserve study company, let

me know and I can pass along a name and number to you.

If you have any questions or would like additional

information feel free to contact me at CraigZ@colleyelevator.com or

630-766-7230 ext. 107.

Nice Blog

ReplyDeleteLift manufacturers in Chennai

Passenger lifts manufacturers in Chennai

Hospital lifts manufacturers in Chennai

Goods lifts manufacturers in Chennai

Lift AMC in Chennai

Modernization of Lifts in Chennai

Awesome information, thanks for sharing.

ReplyDeleteelevator panels suppliers