This

project was at a building that was built in 1967 and the building was

frustrated with the inconstancy of the elevator system and the longer and

longer time it took to get a shutdown repaired and parts. We did not maintain this elevator prior to

modernization and worked with a building a year and half in advance of their modernization

so they had time to get out of their existing maintenance agreement and the

residents had time to prepare for the 4-5 week project.

Machine room layout – One of the big challenges we have when working with older buildings is their existing machine room. This machine room also includes other mechanicals or storage. The project team and electrician where able to work together and get a good spot to get all of our NEC electrical clearances. The old disconnect was tucked behind the elevator motor starter panel.

Hydraulic elevator controller – the original controller is an ESCO relay logic system. Historically these will have open/close relay issues and general relay issues that require an old school relay tester for proper resolution. We replaced this with a new Smartrise hydraulic elevator controller.

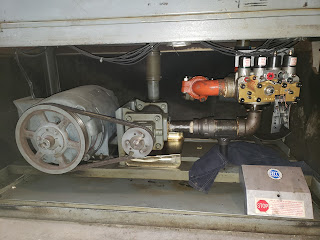

Hydraulic elevator power unit – The existing ESCO power unit was still there with a newer EECO UV5 valve that had been replaced 10+ years ago.

Door operators – Original GAL MOD

operator was replaced with a GAL MOVFR door operator and car and hatch

equipment.

Elevator hall station

fixtures

– The new main landing car station is packed with new devices and needs to be ADA compliant.

Take away – The elevator

modernization was long overdue, most of the equipment was well worn and

serviced the building for many years past its life expectancy. We had a great leadership ground from the

building to work with, a great property management team and our project teams

did great on this. 14 people at Colley

Elevator from the first phone call to the final inspection had touch points on

this project. At times, we forget that

while we have a sales person and a project team there are many people in-between

that help make this project a success.

Hey! Sign up for our mailing list! You get an email once a

month with some of our highlights from the blog and news.

Also

check us out on Instagram @Colleyelevator see what we have been up to.