This

is a story about elevators installed in 2000 by Schindler Elevator. The challenges with these specific cars was

the control platform[no technical support], part availability and

reliability. The campus developed a capital plan for all of their elevators while working with an elevator

consultant. These two were next on the

list to be replaced.

Existing elevator &

project scope

– We replaced the elevator controller, fixtures, door operators with associated

door equipment and the hydraulic power unit.

New

equipment providers

Controllers

– Smartrise Engineering

Door

operators – GAL MOVFR w/new ECI door equipment

Fixtures

– Innovation Industries

Power

unit – MEI with Maxton valves

Elevator controller – The existing elevator

had a Schindler/Westinghouse MPH 2 control system that, in our opinion, needed to be replaced due to reliability issues, proprietary nature of

controller[no technical support] as well as part availability. The new Smartrise control system will allow

the building to have technical support as well as a much easier time getting

parts.

[Existing Schindler/Westinghouse MPH 2 control system]

[New Smartrise Engineering hydraulic elevator controller]

Elevator door operators

– We

replaced the original GAL ECI door operator with a GAL MOVFR door operators and

replaced the ECI door equipment with new ECI door equipment.

[Existing ECI door operators]

[New GAL MOVFR door operators]

Elevator fixtures – We installed

Innovation Industries hall and car fixtures to replace the original Schindler/Westinghouse

fixtures. The new car panel complies with the recently mandated A17.1.2019 code which requires two way visual communications designed for hearing-impaired riders.

[Old Westinghouse/Schindler Elevator car station]

[new Innovation Industries car station with visual text feature]

[This car station has a camera, screen to read text communication and yes and no buttons]

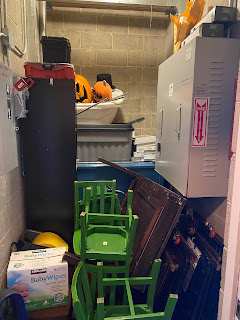

Hydraulic power unit – We removed the

Schindler submersible power unit with UV5 valves and installed an MEI Elevator

submersible power unit with a Maxton UC4 hydraulic control valve. The controllers mounted on the front is easier to install but harder to work on because you need to get on your hands and knees (or bent over) to see everything.

[Existing hydraulic power units with EECO UV 5 valves and controllers mounted on the front]

[New MEI power units with controllers mounted on the wall at eye level so you can easily work on them]

[New MEI valves and inflatable muffler to reduce noise]

Take away – This building has a

plan to replace all of their elevators because they need reliable vertical

transportation for their population. The

building has a plan and list of the elevators in order of need and is

capitalizing them each year to spread out the projects/cost.

Team work– The sales person and

the project team who finishes typically get the glory on a project. In between the initial contract sale and the

final acceptance are many other people who work on the project to make it

successful. From the truck driver to the

engineer to the billing department to the assist when needed 12 Colley Elevator

employees where involved in the project and we had tremendous team work on

it. Thank you everyone without you we

would not have had such a successful delivery!

Let’s not forget our great material supplier participation!

Team work with the

building –

We have a great building owner who we can work with hand and hand with the

challenges that pop up, this helps tremendously to make a smooth project. Great communication, great team work, great

results.

If

you have any questions or would like additional information feel free to

contact me at CraigZ@colleyelevator.com or

630-766-7230 ext. 107.

Also

check us out on Instagram @Colleyelevator see what we have been up to.