This

is meant to be a guide for general contractors when working with an elevator

contractor for a new installation. We

work with GC’s or CM’s that have a variety of experience doing elevators from

doing them on a regular basis to being their first one.

[As contractors we look forward to the day we have a truck onsite]

1st

rule – Do not building your elevator

hoistway without final drawings – Under no circumstance should anyone

building a hoist way without a final drawing.

All elevator systems are not the same.

The mason will need to install connection devices[inserts, tube steel,

etc] in certain places in the hoistway.

The most important thing is you may not build the hoistway for the

elevator you ultimately purchase so it would go from a vanilla installation

price to a custom price because the company you hired doesn’t use the same foot

print. I.E. use a Kone MRL foot print

and end up deciding not to work with Kone, If you building the hoistway for the

Kone elevator, you may have a huge problem with additional costs.

If

you are not familiar with elevator drawings have the elevator contractor come

out and walk you through what you need.

We are not building a rocket ship but we are building something that

requires many different trades to work together.

Hoistway entrances – Pay attention to the

rough opening we will need and keep the entrance that we will be installing the

cab in open so we can get the platform in.

[Wonderful! The 1st landing HW entrance is open]

Hoistway

inserts/connections

– Make sure you know where to put them in the hoist way. As a GC or CM, you may know but whomever is

going to be installing them should also have a good understanding before they

begin constructing the hoistway. On

construction sites I get a lot of “yeah I do this all the time” and people

shaking their heads and we still have inserts installed in the wrong place. If

you have alternate means of connecting the rails to the hoistway work with your

contractor on a solution, do not assume it will work because the

architect/design team said it will.

[Typical wall insert in CMU]

[This building is using tube steel instead of CMU inserts]

Have the elevator pit

ready to go

– Make sure your pit is 48” or 60” or whatever it says on the drawings. You will also need a sump pump that can pump

3000ga per hour, have the hole in. If

you have questions on where it goes, call your elevator contractor for direction and do not put it where you

think it should go, put it where the elevator contractor tells you or where the

drawings show. We have items that go in

the pit that are need to go in a certain spot.

Priority 1 is an elevator installation not making life easy for the

concrete guy or the plumber.

[A prepreconstruction site visit to meet the CM/GC - Pit is getting ready]

[Pit ended up beautiful]

[A recent site visit when a GC told me the hoisway/pit was ready]

Main line power – When you expect the

elevator contractor to start, make sure you have main line power and lights in

the elevator room. Please do not tell us

you have power when you do not, we will come out and work for 8 hours and then

tell you to call us back when you have power and most companies charge you with

a remobilization charge. Lights in the

machine room are important as well. Know

your electrical clearances and where the elevator equipment will be placed

before installing the disconnects.

110vac power in pit and

machine room –

Our tools need to plug into something it is helpful when we have live power in

the machine room and our pit so we can avoid stringing extension cords all over

your building.

Environmental controls – We love

environmental controls HVAC! Be aware

when these are being installed the #1 priority is elevator installation not

making life easier for the HVAC guy. We

have a controller and machine that needs to be placed somewhere if we have a

machine room. In picture we see we have

this wonderful air conditioner with water pipes everywhere. We do not want water pipes in our machine

room.

[Love the HVAC, don't love the water pipes]

Phone line – Get your phone line

ready. You can use a POTs line, VOIP,

Cellular or whatever. When we start have

it waiting and have it be live! We don’t

want to get to the end of the project and not be able to get the elevator

inspection because there is no 2 way communication.

Hoist beam – If you want to make

friends with your elevator project crew put the beam where it is supposed to be

on the drawings. This will make the

project go faster and safer.

[This beam is very important to us when doing our installation]

Staging & delivery- clear out a space

for the elevator contractor so when he starts he has a clear and safe space. Also please have means to have our large and heavy equipment to be unloaded.

[Not a great staging area]

[We appreciate it when we have a clear means to deliver equipment - This construction site did not have a clear means for us to get material in the building]

Trade meeting – Get the trades

together to discuss their scopes and have them ask questions and go over

drawings. The meeting is not about the vanity of the general contractor,

building owner or elevator contractor it is about the successful installation

of a conveyance system that requires all parties to do their part.

[This was a construction meeting that included all trades involved]

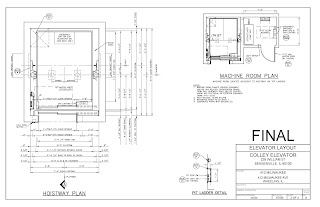

Before

approving drawings understand what is mentioned on the lay out drawings. No matter how many elevators you have

installed please read what is on the new installation front page.

Hoistway and pit

1.

A

clear hoistway to the dimensions on the drawing, plumb within ½” to 1”

total. Hoistway shown is minimum. Any out of plumb condition must not encroach

on hoistway size envelope from top to bottom

2.

Venting

of hoistway as required by code

3.

A

dry pit reinforced to sustain vertical loads as shown.

4.

A

pit ladder for each elevator of non combustible material, constructed and

installed in accordance with code, and extending from pit floor to 48” above

sill of lowest hoistway door.

5.

Adequate

supports for guide rail brackets, to support horizontal loads as shown. Support locations must not exceed spacing as

required by code, and as shown. When

maximum spacing is exceeded, rail reinforcement, or added supports must be

provided at purchaser’s expense.

6.

Guide

rail support location must be steel, brick, concrete, or filled concrete

block. Inserts, if used, are supplied

and installed by others, in locations shown, as walls are erected. If rail brackets are attached to steel beams,

fire proofing is to be applied after rail brackets are installed.

7.

Permanent

provisions shall be made to prevent accumulation of water in hoistway pit per

ASME A17.1

8.

Projections

or recesses in hoistway of 4” or more, on sides not used for loading or

unloading, shall be beveled at an angle not less than 75 degrees from the

horizontal.

9.

A

hoist beam, book or eyebolt shall be furnished at the top of hoisway located on

centerline of car and guides – designed for load capacity of 6000lbs minimum.

10.

Entrance

walls accepting passenger type entrances are to be erected(or rough opening as

shown filled in] after door frames and sills are installed

11.

A

suitable sill support and recess as shown, full width of hoistway, grouted by

others after door sills are installed.

12.

Required

sleeves in hoistway walls, or any trenching and filling, for oil line and wire

duct for each elevator, as shown.

13.

Any

cutting and patching of building construction required to install signal

fixtures or other elevator apparatus and any repairs, grouting, patching or

painting made necessary by same

14.

Barricades

may be required during construction – hoistway protection

15.

Hoistway

shall have means to maintain temperature between 40 degrees and 105 degrees

Control Space

16.

A

properly lit and ventilated control space per code requirements, with temperature

maintained between 55 degrees and 90 degrees.

Door size show to permit access for machine.

17.

Machine

room to be designed and laid out to comply with electrical clearance

requirements and maintenance clearance requirements. Elevator contractor’s equipment is priority

here not the plumber, HVAC, electrician, security or fire alarm equipment. If their equipment is in the way, they will

need to move it.

Electrical & pit –

All electrical in accordance with ASME and NEC

18.

A

fused disconnect switch for each elevator, of ample capacity, wirth wiring to

the elevator motor starter control.

Disconnecting means shall disconnect the normal power supply as well as

emergency supply, when provided.

19.

Light

and switch in elevator control space, with switch located adjacent ot the

access door. Convenience outlet in

control space[GFI].

20.

Light,

switch and convenience outlet in elevator pit, light switch accessible from

lower landing opening. Install light to

clear elevator car.

21.

Suitable

110v service in the hoistway, midway of travel[see layout] or connected to

terminals in elevator controller for car light service[elevator contractor

option]

22.

Heat,

and product combustion sensors located in each elevator lobby with necessary

wiring to elevator control panel, when fire service is required

23.

If

sprinklers are present in the control space or hoistway, a means shall be provided

to automatically disconnect the mainline power supply prior to the application

of wire[shunt trip].

24.

All

items shall conform to local building code

25.

Relative

humidity not to exceed 85%

Take away - If we all work together and follow the general guide lines given by a good/competent elevator contractor/new construction team we can go from a muddy construction site to a beautiful lobby with running elevators.

[beginning]

[End]

If

you have any questions or would like additional information feel free to

contact me at CraigZ@colleyelevator.com or

630-766-7230 ext. 107.

Also

check us out on Instagram @Colleyelevator see what we have been up to.