A property management firm we work with called us for a building they take care of that was considering modernization on their elevator equipment. I started giving the building pricing in 2005 for maintenance and other work. When we went to the building we saw they had a Vertitron VH 40 controller that is obsolete and gave them a recommendation to modernize. A few months later we were invited to the building and had a great meeting with the Condominium Board. We were fortunate enough to be awarded the project.

Existing elevator & project scope – We replaced the elevator controls, fixtures, wiring and door operator. The building retained a great power unit from our friends at Quality Elevator that was still in good condition.

New equipment providers

Controllers – Smartrise Engineering

Door

operators – GAL MOVFR

Fixtures

– Innovation Industries

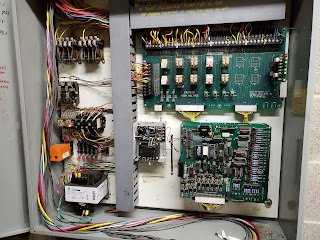

Elevator controllers – The existing controller was a hydraulic elevator controller manufactured by Vertitron Midwest – Mankato, MN in 1995. This elevator system is not supported any longer[obsolete] and is a coin flip if the boards can be repaired. We replaced it with a Smartrise Engineering hydraulic elevator controller.

Elevator door operators – We replaced the MAC door operator with a GAL MOVFR II door operator and replaced all the hatch and door equipment while retaining the door tracks.

Elevator fixtures – We installed Innovation Industries hall and car fixtures which was a good upgrade cosmetically for the building. This car station is equiped with the new State of Illinois adopted A17.1 2019 code which requires visual items; camera & texting.

Take away – Importance of having a board meeting – One of the greatest things about this project was having a meeting with the Board prior to the signing of the modernization proposal. We spent about an hour talking through the process and answering questions. When it came time to mobilize everyone on the board was ready and educated. When we turned the car over, they knew what to expect. I encourage all buildings to have a meeting with the key players in the building so you can go over expectations, challenges, work by others and anything else that is topical to the building. It makes a project go much smoother.

Team work– The sales person and the project team who finishes typically get the glory on a project. In between the initial contract sale and the final acceptance are many other people who work on the project to make it successful. From the truck driver to the engineer to the billing department to the assist when needed 9 Colley Elevator employees where involved in the project and we had tremendous team work on it. Thank you everyone without you we would not have had such a successful delivery!

If you have any questions or would like additional information feel free to contact me at CraigZ@colleyelevator.com or 630-766-7230 ext. 107.

Also check us out on Instagram @Colleyelevator see what we have been up to.

No comments:

Post a Comment