Over the last two months we have had a large amount of questions on the typical WBO, or work by other, scope for elevator modernizations. This is a relatively comprehensive WBO list that should work for 95% of the projects Colley works on.

Elevator Electrical

The elevator electrical is as follows:

Shunt Trip Disconnect System

Shunt trip disconnect is required on any new or existing elevator where a sprinkler is located at the top of the hoistway or in the machine room. Note that a properly located sprinkler in the pit only, will not cause shunt trip disconnect to be required.

Non-sprinklered elevators will not have a shunt trip disconnect system.

The shunt trip disconnect is as follows:

110 VAC Car Lighting Disconnect

The elevator electrical is as follows:

- Heavy duty fused main line disconnect w/earth ground.

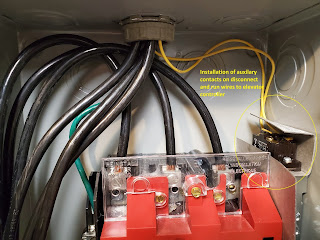

- If battery lowering is present, have auxiliary contacts installed.

- If building generator that powers elevator is installed, have wires from generator to elevator controller for emergency power contact and power pre-transfer contact.

Shunt Trip Disconnect System

Shunt trip disconnect is required on any new or existing elevator where a sprinkler is located at the top of the hoistway or in the machine room. Note that a properly located sprinkler in the pit only, will not cause shunt trip disconnect to be required.

Non-sprinklered elevators will not have a shunt trip disconnect system.

The shunt trip disconnect is as follows:

- Must cause disconnection of normal power and emergency/stand-by power.

- It must also cause disconnection of any internal auxiliary power operations, such as battery lowering devices, on hydraulic elevators or anti-entrapment (TAP) devices on traction elevators if so equipped. The shunt trip disconnect must have a set of contacts that signal the control system to prevent movement of the elevator.

- Power to and operation of the shunt trip shall be independent of the elevator control and shall not be self-resetting.

- Location of the shunt trip disconnect is not specified by code. Shunt trip disconnect can be in a fire command center, elevator machine room, electrical room, or other location. If in the machine room, it may be combined with the main disconnect.

- City of Chicago discourages shunt trips[check with DOB prior to installation]

[Separate disconnect & shut works]

[Combo unit works]

110 VAC Car Lighting Disconnect

Car lighting disconnects are as follows:

Single non GFCIs outlet for sumps.

Adequate lighting in pit and machine room – 4’ LEDS work great for the pit.

Pit light switch accessible & adjacent from hoist way door.

Duplex GFCI protected outlet in pit area and machine room

*All items must comply with NEC section 620 – pay mind to electrical clearance requirements and label sources.

GFCI’s in the elevator machine room and pit

Elevator Fire Alarms – Fire Alarm Initiating Devices (FAIDs)

These shall be installed as follows:

- Fire recall detectors at each landing.

- Smoke detectors on ceilings must be at least 4” from the wall.

- Smoke detectors on walls must be between 4” and 12” from ceiling (see image)

Fire recall detector in the elevator machine room

Fire recall relays in elevator machine room

Fire recall detectors are required at the top of the hoist way when either a sprinkler is present or the passenger cab is not fire rated. If a cab is not fire rated, you can also get fire resistant paint instead of installing sprinklers.

NO smoke detectors shall be provided in the elevator per NFPA 72.

If a sprinkler is 24” above pit floor you must provide a heat detector – if you provide a heat detector, you must provide a smoke detector. If sprinklers are 24" above pit floor you may be required to move them to below 24"[address with AHJ prior to installation].

Heat detector must be located within 24” of a sprinkler.

*all items shall comply with NFPA 72 or local AHJ rule or funding entity rule such as IDPH or other authorities that may require rules that may be different than NFPA or NEC requirements. If you don’t know, find out.

Other items we may need a building to provide include:

- A fire rated machine room & hoistway

- Fire rated doors – labeled w/rating

- Self closing self locking machine room door

- 12” x 12” fused louver ventilation in machine room (see image)

- Internet connectivity – a CAT 5 cable for elevator camera and texting if the building is located in the suburbs (not City of Chicago) to comply with A17.1 2019 audio/visual code requirements

- Temperature and humidity controlled machine/control rooms – 55 to 80 degrees & 0 to 85% humidity

Take away – Educate yourself on the work by others so when we have your elevator inspected, we can have a cleaner inspection and less items on the punch list. These are easy ones to address before, during or shortly after a modernization is completed.

If you have any questions or would like additional information feel free to contact me at CraigZ@colleyelevator.com or 630-766-7230 ext. 107.

Also check us out on Instagram @Colleyelevator see what we have been up to.

I have not checked in here for a while because I thought it was getting boring, but the last few posts are good quality so I guess I’ll add you back to my daily bloglist. You deserve it friend :)safety decking systems

ReplyDeleteImpressive WBO Elevator Modernization, enhancing safety and efficiency seamlessly. Great job! FMC Fire Systems

ReplyDeleteThank you so much for sharing this informative post. Really i got exact information what i was searching Electrical Fire to know about our service.

ReplyDelete