This is another building we did an incredible modernization project on that improved the reliability of the elevator system. We had been talking to the building about equipment replacement since we took over the account 2012 to start giving them a chance to budget for this major project.

Existing elevator & project scope – The existing equipment in the building where Montgomery Mi Prom 7 story hydraulic elevators. In Des Plaines, IL there are a lot of MiProms and a lot of US Elevators. Neither MiProm or the US Elevator are user friendly controller, unless you are a Montgomery or US elevator mechanic that grew up on these. The good news is that a lot of the existing control systems are to a point where they are getting replaced.

New equipment providers

Controllers

– Smartrise Engineering

Power

units – MEI

Door

operators – GAL MOVFR II w/MAC car and hatch door equipment

Fixtures

– Innovation Industries

Hydraulic elevator

controller

– The original controllers have been through a lot including undersized original

mainline disconnect wiring and very hot machine rooms. Look at the difference in how many wires and

boards from the old Miprom control system to the new Smartrise system.

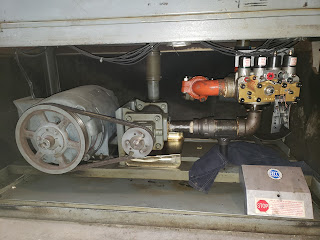

Hydraulic elevator

power unit

– The old Montgomery power unit was wearing and experiencing fatigue. It also was leaking a decent amount. This replacement was part of phase I which occurred

a few years prior.

Door operators – The elevator had MAC

operator and equipment. We replaced the

operator with a GAL MOVFR and replaced the existing MAC equipment with new to

reduce some of the expense with replacing with all GAL.

Elevator fixtures – The old Montgomery fixtures went away and new Innovation flush mount fixtures to meet ADA and elevator code requirements were installed. Originally there was only 1 button stack so we put the new button stack on the other elevator to eliminate any downtime. We also combined the directional arrow with a position indicator because the original man lobby fixture was already busy with all the devices, when adding the emergency communication, it became challenging to make everything fit.

Take away – The big take away for this project was that a building planned for many years to do the project. We started working with the building in 2015 on budgets and phasing. We broke this project up into 3 phases many years ago; power units & soft starts, door operators and finally the control and operating system. Eventually we decided to wait to complete phase 2 and 3 together and kept the cars running an additional year so it could all be done at the same time.

Hey! Sign up for our mailing list! Each month you will get

some great info on Colley! It is short

and quick to run through, you’ll like it!

If

you have any questions or would like additional information feel free to

contact me at CraigZ@colleyelevator.com or

630-766-7230 ext. 107 or on our web page at www.colleyelevator.com

Also

check us out on Instagram @Colleyelevator see what we have been up to.